METODOLOGY

The research methodology used by the group Robolution Loyola Team is based on the PDCA model (Plan, Do, Check and Act), which allows feedback to the system for continuous improvement.

Transverse to the whole development project a literature review was conducted in indexed databases, books and other primary and secondary sources.

4.1 DESIGN:

At this stage was made step by step planning of all activities to be undertaken throughout the project, specific tasks were assigned to each team member and worked in parallel in several respects:

• Modeling: We design patterns 3D housing and infographics operation.

• Biological Research:

Visits were made to various chain stores and market places of the city in order to observe the different factors that can affect the fruits and vegetables, such as handling by customers and employees of the place, without the precautions.

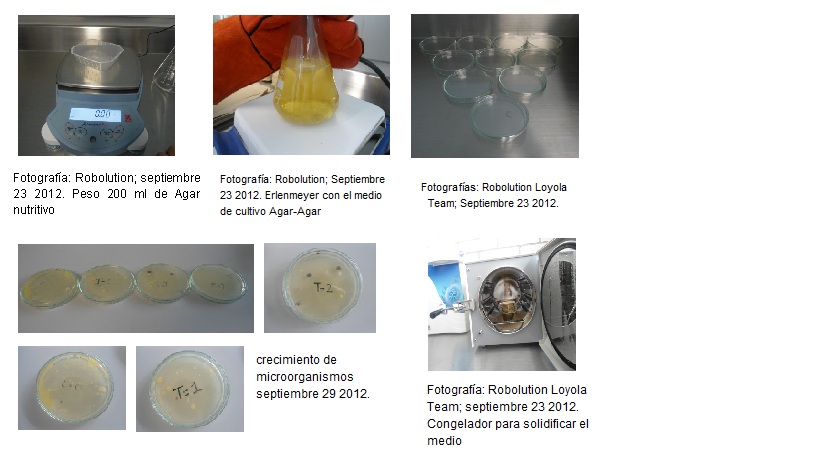

Apple samples were purchased from different outlets, plated in culture medium to identify microorganisms and brought to incubation at 37 ° for 48 hours.

We conducted a literature review in which they found the results of investigations that have been made about the microorganisms present in fruits and vegetables exposed to the environment.

• Electronic design:

The central electronic system of the device is composed of two plaques Arduino, which are composed of several Shields, and communicate with each other so that the prototype function properly.

Each of the plaques is comprised of four components:

An Arduino micro controller, which is responsible for processing all the information, control each of the sensors and communicate the computer and the storage device.

An Ethernet Shield, which is responsible for receiving and sending data through a router to an IP address, for which the owner receives the data, alarms and messages that need to control your device.

A work platform that makes a bridge between the Arduino and the sensors, thereby performing a more suitable and efficient implementation.

An XBee platform, whose main task is to communicate information between the two plaques, the plate number 2 plate sends information to the recipient number one through this component.

RH sensor (Ref. HIH-4030) measures variations in the relative humidity inside the device, these values are part of a control system which maintains the fresh fruit.

Temperature sensor (Ref. LM35) measures variations in the temperature inside the device, these values are part of a control system which maintains the fresh fruit.

Ultrasound sensor (Ref. LV MaxSonar-EZ4): measures the amount of fruits found in the prototype.

• Web Pages:

Were designed two pages: one page created in HTML to help the owner to have proper control of each of your devices, this site has a database made in MYQSL, where are stored all the data it receives from the sensors.

Another elaborate on a free web page creator "Wix" for customers, who can log in from their mobile devices through QR codes.

•System inventory:

The inventory system is based on detection of the volume of fruit in the basket by means of an ultrasonic sensor which detects the distance of the objects that have in front. The basket containing the fruit is inclined, whereby, when being pulled fruits, which are accumulating in the lower part of the sensor and distance.

The measured distance is an indicator of the volume of fruit, based on a level measurement. All this information is sent to the page owner, by an alarm system at the time that the prototype fruit begins to run out.

4.2 CONSTRUCTION

ON-OFF Controller

The controller used is On-Off, one of the simplest in control theory. This Search compare the output of the system with a reference value or set-point, so that always sensed value is equal to the reference.

Here are the steps to implement the control system electronically:

- Conversion of analog signal from the sensor HIH-4030 digital signal into the Arduino

As the signal from the sensor is voltage, we must examine the data sheet, which is the curve relating this physical variable to measure relative humidity. The curve is shown below:

As the signal from the sensor is voltage, we must examine the data sheet, which is the curve relating this physical variable to measure relative humidity. The curve is shown below:

- Programming the Arduino

With the transfer function of the relative humidity control is performed via this microcontroller. Also were scheduled motion functions of gates, gel activation temperature, ultrasound and communications.

• Measurement of Ethylene

• Measurement of Ethylene

Proposed in this phase, a measurement Ethylene because fruits release gases when they are in the decay process, which may be an indicator of the quality of the fruit that are in the device.

The sensor used is a MQ-4 Gas sensor, which has the ability to measure various gases, as indicated by the graph, where the value obtained in the measurement is expressed in parts per million and depends on the calibration of the sensor, given by an arrangement of resistances. In our case the cure of interest is that of CH4, represented by purple boxes.

The resistance value MQ-4 is different for different types of gas concentration. Therefore, the sensitivity adjustment is very necessary to ensure a good measure.

Bearing in mind the recommendations of the detector was calibrated datasheet for 5000 ppm CH4 concentration in the air. This was accomplished by using the value of the load resistor (RL) close to a value of 20 kOhm.

• Inventory System

The inventory system is based on detecting the amount of fruit in the basket by means of an ultrasonic sensor which detects the distance of the objects that have in front. This principle is used as the basket is inclined, whereby, when being pulled fruits, which are accumulating in the lower part of the sensor and distance.

The measured distance is an indicator of the volume of fruit, based on a level measurement. All this information is sent to the page owner, by an alarm system at the time that the prototype fruit begins to run out.

• The construction of the prototype dispenser:

We kept in mind the design made in 3D, which served as the basis for making molds for both acrylic as for aluminum. Then he proceeded to cut the various parts, assembling, pasting and finally assemble the entire system.

We kept in mind the design made in 3D, which served as the basis for making molds for both acrylic as for aluminum. Then he proceeded to cut the various parts, assembling, pasting and finally assemble the entire system.

Photo from Robolution Loyola Team, march 2013.

4.3 TESTS:

In this stage, the different tests were carried out of the electronic components of the prototype. We proceeded to check the durability of fruit (pear and apple) in and out of the container.

Retrieved QR code generator, we test with multiple mobile devices and it was found that dovetails nicely with the website.

4.4 NEGOTIATION

It presented the project to a chain store that suggested some changes to the project that would meet current market needs. We performed a prospective analysis for the screening of development and create business strategies for this.

4.5 ANALYSIS OF RESULTS

From what obtained in the tests and recommendations chain store, we performed a detailed analysis of which were some adjustments to the system.

5. RESULTS

Biological:

§ The organisms found in the environment, have the ability to react to change and some adapt to new environments, which cause disease in humans. Among the most common in fruits and vegetables are:

|

Microorganismo |

Nombre genérico |

Enfermedades que causa |

|

Eschericchia coli |

E.Coli |

Infecciones intestinales, la neumonía, la meningitis, dolor de cabeza, diarrea hemorrágica. |

|

Salmonella typhi |

Salmonella |

Diarreas, afección de la parte superior del aparato respiratorio; inflamación de articulaciones, meninges, testículos, y abortos. |

|

Bacilluscereus |

Bacillus |

Vómito, diarrea, nauseas, infección ocular y traumatismo en el ojo. |

|

Clostridium sporogenes |

Clostridium |

Visión borrosa o doble, debilidad general, reflejos pobres, dificultad para tragar, respirar o hablar, vértigos, parálisis flácida y, a veces, la muerte por insuficiencia respiratoria. |

|

Klebsiellapneumoniae |

Klebsiella |

Rinitis atrófica, infección abdominal. |

|

Enterococcus spp

|

Enterococcus |

Endocarditis, infecciones de piel, tejidos blandos, infecciones urinarias, y heridas quirúrgicas. |

Made biological analyzes of samples of apples, have found that pathogens that can affect the health of the consumer.

As for the handling, sampling was done in several outlets in the city of Medellin and the data obtained show that fruits and vegetables are exposed to contamination by handling customer before being purchased between 9 and 15 times in addition to receiving sneezing 6 to 8 times. As shown in the following graph:

|

PRODUCTO |

N° manipulaciones por hora |

N° estornudos encima del producto por hora |

|

|

MANZANA |

9 |

7 |

|

|

PERA |

10 |

6 |

|

|

TOMATES |

15 |

8 |

Modular Electronic System:

§ Humidity and Temperature Control

As for the necessary parameters to maintain the quality of fruits and achieve longevity is important to keep the humidity and temperature control:

|

Producto |

Temperatura |

Humedad Relativa |

Vida aproximada de almacenamiento |

|

|

°C |

°F |

(%) |

||

|

Apples (Manzanas) |

-1 a -4 |

30 a 40 |

90 a 95 |

1 a 12 meses |

|

Pears (Peras) |

-1.5 a - 0.5 |

29 a 31 |

90 a 95 |

2 a 7 meses |

Control operation of RH is given by the graph representing the transfer function of the humidity sensor, where two points are selected to obtain a straight line, simplifying the model, since the linearity can be seen from it.

Points are taken:

Points are taken:

![]() and

and ![]()

![]() The model of a linear equation is given by:

The model of a linear equation is given by:

Where m is the slope and b the intercept with the y-axis, whereby the first step is to find the slope by means of the formula:

![]()

Therefore m for this model is given by

![]()

The intercept with the y axis, that is to say b, is taken directly from the graph, is

![]() The equation of the line is defined by

The equation of the line is defined by

Replacing the physical variables:

![]()

Where the last is obtained in the relationship between voltage and humidity, yet the process has not ended, since the value sensed by the microcontroller, is not directly expressed as a measurement of voltage, but a value proportional to the scale of resolution in bits, which in this case is 10 bits.

The amount of digital words or values in resolution, is calculated with the formula, where n is the value of bits, and bit 2 is the base of the microcontroller, so for this case, the number of digital words are given by:

![]()

Each digital word translates a voltage value, which is given as the voltage window that covers the resolution, which for Arduino is 5V, whereby each word or value change means an increase or decrease in, whereby delivered as very reliable.

With this in mind, we must change the equation, the units of voltage, digital words, bearing in mind that, ie there are 204.8 per volt words, the equation is then:

![]()

![]() In this equation the variable HR must clear, as is that we obtained from the measurement of the sensor, therefore

In this equation the variable HR must clear, as is that we obtained from the measurement of the sensor, therefore

Arduino Programming: With the equation derived above, you can get the value of HR so you can control the system from the reference signal to be maintained, the Arduino code to control the actuator on or off from HR value, is as follows:

#include

#include

#define ONE_WIRE_BUS 2

OneWireoneWire(ONE_WIRE_BUS);

DallasTemperaturesensors(&oneWire);

constintledPin = 13; // Este es el pin que se debe encender después de la comparación

inthr=0; //Variable HR

void setup() {

pinMode(ledPin, OUTPUT); //puerto 13 como salida, es el LED

Serial.begin(9600); //puerto com 11 9600Bd }

void loop() {

hr=((analogRead(A0)-163.84)/9.01); //Formula obtenida

//Aqui se envían los datos al puerto com

Serial.print(hr/10);

Serial.print(hr%10);

if(hr>85)// esta es la señal de referencia, abajo están las líneas del controlador

digitalWrite(ledPin, HIGH);

elsedigitalWrite(ledPin, LOW); }

§ Inventory Control

The inventory system detects that the volume is in the basket by means of the ultrasonic sensor. The basket containing the fruit is tilted, whereby, when being pulled fruits, which are accumulating in the lower part of the sensor and distance.

All this information is sent to the page owner, by an alarm system at the time that the prototype fruit begins to run out.

§ Web Pages:

- One for the customer: we used the free website wix.com. The page contains nutritional information, ideal environment, recipes and fun facts for fruit, especially apples and pears, which are the object of study. Then use a QR code generator to bind to the website and that in this way the users can obtain from their devices.

web: https://robolutionloyolateam.wix.com/fruits-hangar#!home/mainPage

-Another of the owner, it allows the business owner or manager of inventory, permanently monitor the product.

Prototype:

The construction and assembly of the prototype took place with satisfaction